Choosing the right excavator can make a massive difference to your project’s success. The right machine keeps your job running smoothly, safely, and efficiently, while the wrong one can slow things down, chew through fuel, and add unnecessary costs.

Whether you’re managing a large-scale mining operation or a mid-sized earthmoving job, picking the right excavator is all about matching machine capability to the task at hand.

In this guide, we’ll break down the key things to consider, from size and bucket capacity to ground conditions and fuel efficiency.

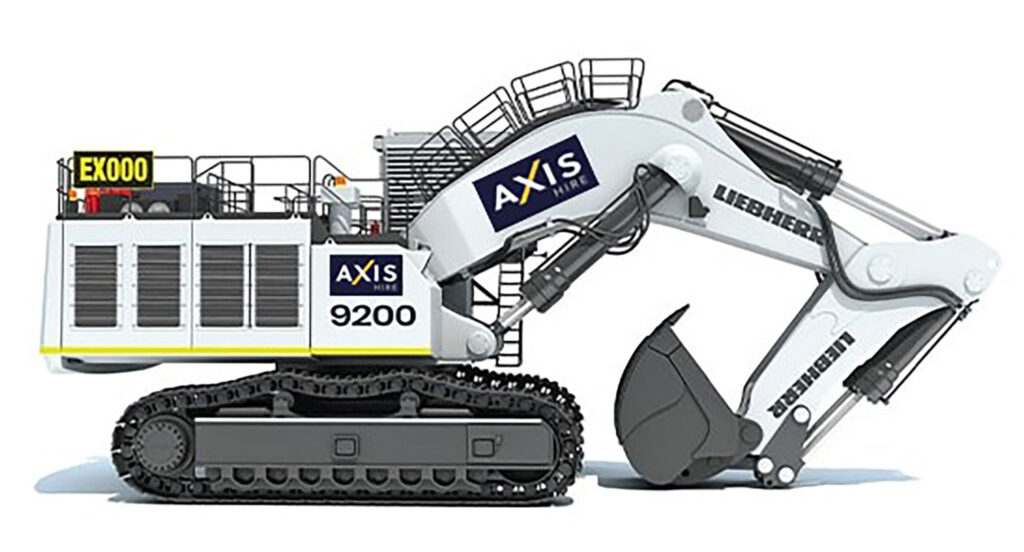

We’ll also highlight three proven performers available for hire from Axis Hire – the Liebherr R9200, Liebherr R9150, and Komatsu PC1250-11R – and explain how each one suits different site demands.

Why Choosing the Right Excavator Matters

Excavators are a big investment, even when you’re hiring. The right machine helps you work faster, use less fuel, and get better results. The wrong one? It can lead to poor digging performance, more maintenance, and wasted time.

Axis Hire will always match the excavator type to our customers’ needs to:

- Boost productivity and cycle times

- Reduce wear on components

- Lower running costs through better fuel economy

- Improve site safety and operator comfort

It all starts with understanding your project requirements, the scope, material type, and how long the machine will be in use each day.

Know Your Project

Every job is different, and so are the demands on your equipment. A massive mine site needs a very different setup to a civil construction job or quarry operation.

Axis Hire will start their assessment of your requirements with a few key questions:

- What’s the overall size and scope of the job?

- How deep or wide do you need to dig?

- What material are you moving — rock, soil, sand, or mixed ground?

- How many hours per day will the excavator be operating?

For big mining projects, you’ll want serious digging power and endurance. Axis Hire currently has machines available for hire like the Liebherr R9200 and Komatsu PC1250-11R which are purpose-built for this kind of heavy-duty, around-the-clock work.

Match Size and Power to the Job

Excavators range from small 1-tonne machines to massive mining rigs weighing hundreds of tonnes. The trick is choosing one that’s big enough to do the job efficiently — but not so big it’s overkill.

Excavator types:

- Mini (1–10 tonnes): Compact and perfect for small jobs or tight spaces

- Medium (10–35 tonnes): The go-to for most construction and infrastructure work

- Large (35+ tonnes): Designed for mining, quarrying, and major earthmoving

In mining, bucket size and digging depth are everything. That’s where machines like the Liebherr R9200, with its 12.5 m³ bucket and 773 kW engine output, really stand out. It’s built to move serious material, fast, and efficiently.

Get the Right Bucket Capacity

Bucket size directly affects how much you can move per cycle — and your overall productivity.

Go too small, and you’ll waste time on extra passes. Go too large, and you risk overloading trucks or putting strain on the excavator.

For most mining and heavy earthmoving projects, balance is key.

- Liebherr R9150: With a 9.6 m³ bucket, this model offers quick cycle times and excellent fuel economy.

- Komatsu PC1250-11R: Packs 1100 horsepower, perfect for loading rock or stripping topsoil.

Both are popular on Australian sites because they’re reliable, powerful, and easy to maintain, and both area available for immediate hire through Axis Hire.

Consider the Ground You’re Working On

Your site conditions play a huge role in picking the right excavator. Rocky, uneven, or soft ground all demand different machine setups.

A few things to think about:

- Ground conditions: Wide-track models handle soft or muddy surfaces better.

- Tight spaces: Look for shorter tail swing designs.

- Material type: Hard rock calls for higher breakout force and reinforced buckets.

The Liebherr R9200 and R9150 are both designed for tough terrain, with heavy-duty undercarriages and strong breakout forces. The Komatsu PC1250-11R, on the other hand, uses an advanced hydraulic system that automatically adjusts to varying ground conditions for smoother digging and lifting.

Fuel Efficiency and Running Costs

Fuel is one of the biggest costs in any operation, so efficiency is critical. Modern excavators are designed to use less fuel without sacrificing performance, and that’s a win for both your wallet and the environment.

Efficiency highlights:

- Liebherr R9200: Up to 10% better fuel economy thanks to an advanced hydraulic system and V-engine design.

- Liebherr R9150: Low specific fuel consumption and reduced CO₂ emissions.

- Komatsu PC1250-11R: Tier 4-compliant engine tech for lower emissions and strong performance.

Hiring newer, fuel-efficient machines helps reduce total running costs and keeps your operation aligned with Australia’s growing sustainability standards.

Keep Your Operators Comfortable and Safe

Operator comfort has a direct impact on safety and productivity. Long hours in the seat can lead to fatigue, so a comfortable, well-designed cab makes a huge difference.

Machines like the Liebherr R9200 and Komatsu PC1250-11R feature:

- Air-suspended seats and ergonomic layouts

- Climate-controlled cabins for hot Aussie conditions

- Smooth, responsive controls

- Cameras and visibility aids for safer operation

The Liebherr R9150 also includes extra noise insulation and vibration dampening — ideal for long shifts in noisy environments.

Plan for Maintenance and Minimise Downtime

When your excavator goes down, your project stops. That’s why easy maintenance and strong OEM support are so important.

At Axis Hire, every excavator is maintained to manufacturer standards to minimise breakdowns and keep you on schedule.

When comparing machines, look for:

- Ground-level access for servicing

- Modular components that are easy to replace

- Remote monitoring to spot issues early

- Reliable after-sales support

Hiring vs Buying — What Makes More Sense

Buying heavy machinery ties up a lot of capital, which isn’t ideal if your project timeline or scope changes.

Hiring gives you flexibility and access to top-tier equipment without the long-term commitment.

Hiring from Axis Hire means you can:

- Access late-model, well-maintained machines

- Scale your fleet up or down to match demand

- Avoid ongoing maintenance costs

- Stay compliant with the latest safety and emissions standards

With current hire options available for the Liebherr R9200, Liebherr R9150, and Komatsu PC1250-11R, Axis Hire can provide you with high-performance mining excavators without the financial strain of ownership.

Real-World Example

Let’s say you’re working on a large iron ore project in WA.

Recommended machine: Liebherr R9200

Why: Its 12.5 m³ bucket, 773 kW engine, and strong fuel efficiency make it perfect for pairing with 140-tonne haul trucks.

For smaller or mid-size operations, the Liebherr R9150 or Komatsu PC1250-11R are smart alternatives, offering plenty of power while being easier to move between sites.

All are available for flexible hire through Axis Hire, backed by expert service and support to keep your operation running at full speed.

Ready to Get Started?

Speak with the team at Axis Hire today to discuss your site requirements and discover how the right machine can make all the difference. Find the right excavator for your next project at axishire.com.au.